Unveiling The Power Of Process Maps In Six Sigma

Unveiling the Power of Process Maps in Six Sigma

Related Articles: Unveiling the Power of Process Maps in Six Sigma

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to Unveiling the Power of Process Maps in Six Sigma. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Unveiling the Power of Process Maps in Six Sigma

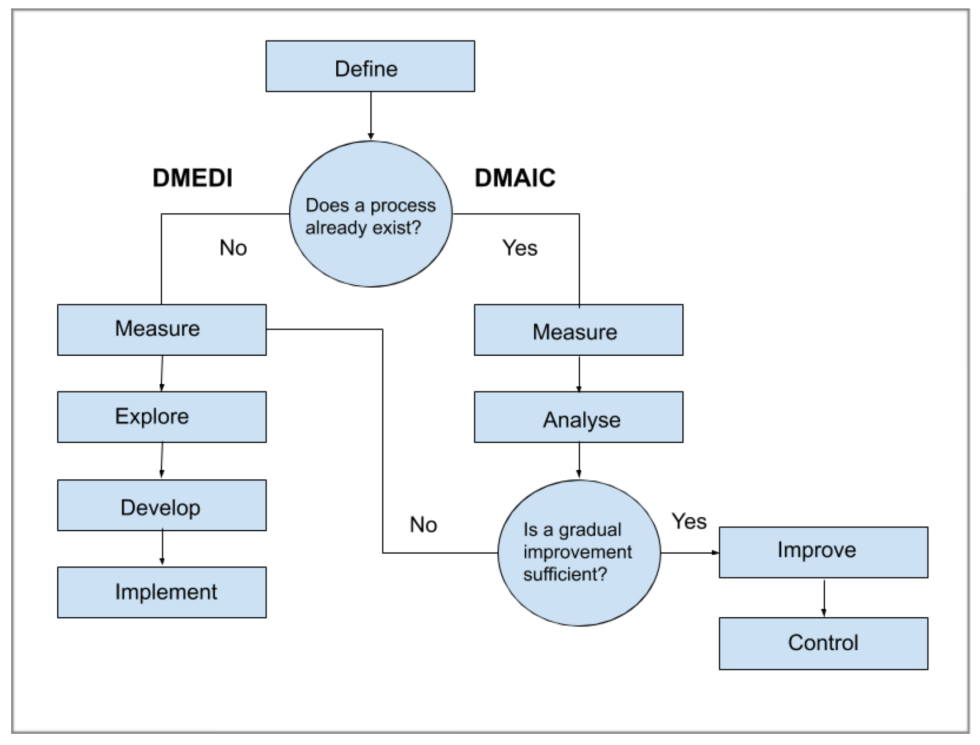

Six Sigma, a data-driven methodology for process improvement, thrives on a fundamental principle: understanding and optimizing processes to eliminate defects and enhance efficiency. At the heart of this methodology lies the process map, a visual representation of a process’s flow, outlining each step, decision point, and potential bottleneck. This article delves into the intricacies of process maps in Six Sigma, elucidating their significance and practical applications.

Understanding the Essence of Process Maps

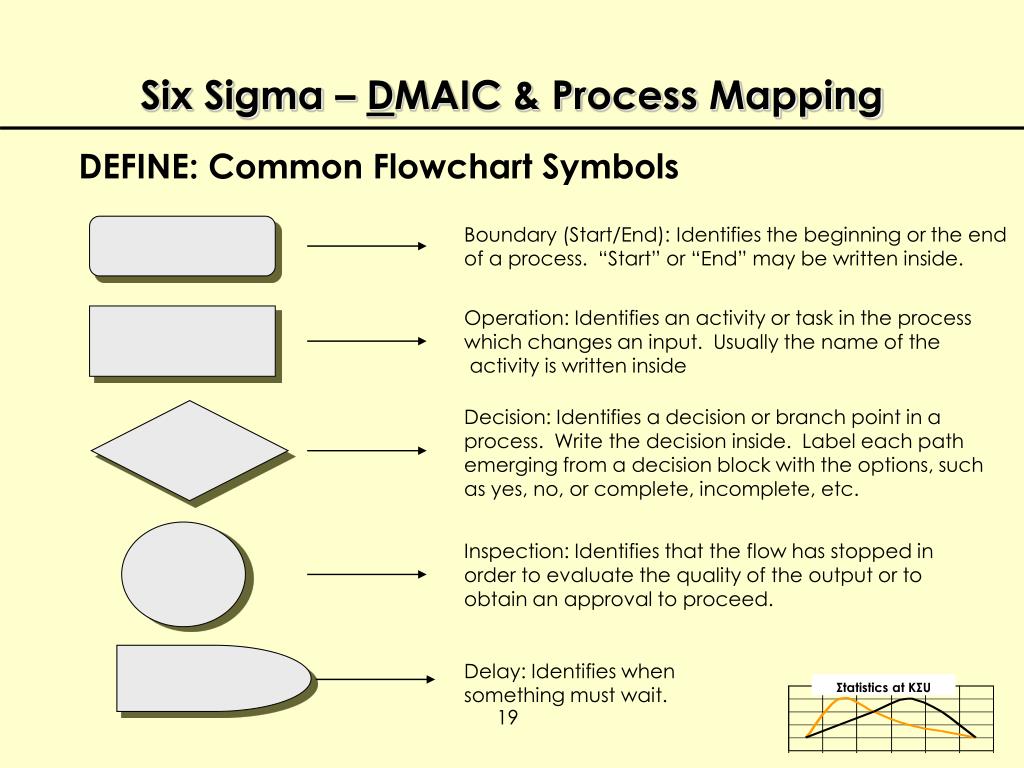

A process map, also known as a flowchart, provides a comprehensive overview of a process, depicting its steps, inputs, outputs, and interactions with various stakeholders. It serves as a visual blueprint, facilitating clear communication and understanding of how a process functions.

Types of Process Maps

Process maps can be categorized into various types, each tailored to specific objectives:

- High-Level Process Map: Offers a broad overview of a process, highlighting major stages and interdependencies.

- Detailed Process Map: Delves into the specific steps and activities within a process, showcasing intricate details.

- Swimlane Process Map: Depicts the responsibilities of different departments or individuals involved in a process, using distinct lanes to represent their roles.

- Value Stream Map: Focuses on the flow of value creation in a process, identifying non-value-adding activities that can be eliminated.

Crafting Effective Process Maps

Developing a process map requires meticulous attention to detail and a structured approach:

- Define the Process Scope: Clearly define the boundaries of the process being mapped, ensuring its scope is well-defined.

- Identify the Process Steps: Break down the process into individual steps, capturing all activities involved.

- Determine Inputs and Outputs: Identify the resources and materials required at each step (inputs) and the deliverables produced (outputs).

- Include Decision Points: Highlight decision points within the process, indicating the criteria for choosing different paths.

- Represent Relationships: Illustrate the relationships between different steps, including dependencies and interactions.

- Use Standard Symbols: Employ standardized symbols for clarity and consistency, adhering to recognized notations like BPMN (Business Process Model and Notation).

- Validate the Map: Ensure the accuracy and completeness of the map through review and validation by stakeholders involved in the process.

Benefits of Process Mapping in Six Sigma

Process maps are not merely visual representations; they serve as powerful tools for process improvement, offering numerous advantages:

- Enhanced Process Understanding: Process maps provide a clear and comprehensive view of how a process functions, facilitating shared understanding among team members.

- Identification of Bottlenecks: By visualizing the flow of work, bottlenecks and inefficiencies become readily apparent, enabling targeted improvement efforts.

- Improved Communication: Process maps serve as a common language for communication, fostering collaboration and alignment among stakeholders.

- Streamlined Processes: By identifying redundant steps and eliminating unnecessary activities, process maps contribute to process simplification and efficiency.

- Reduced Variability: Understanding the process variations through mapping helps in identifying and minimizing sources of variability, leading to more consistent outcomes.

- Data-Driven Decision-Making: Process maps facilitate the collection and analysis of data, enabling informed decision-making based on objective evidence.

- Increased Efficiency: Optimizing processes through mapping leads to reduced cycle times, lower costs, and improved productivity.

- Improved Customer Satisfaction: By improving process quality and efficiency, process maps contribute to enhanced customer experience and satisfaction.

Process Mapping in Action: Real-World Examples

The application of process maps extends across diverse industries and functions:

- Manufacturing: Mapping production processes to identify areas for optimizing material flow, reducing downtime, and improving quality control.

- Healthcare: Visualizing patient care pathways to streamline processes, reduce wait times, and enhance patient safety.

- Finance: Mapping financial transactions to ensure accuracy, efficiency, and compliance with regulations.

- IT: Mapping software development processes to improve code quality, reduce bugs, and accelerate delivery timelines.

- Customer Service: Mapping customer service interactions to identify areas for improving response times, resolving issues faster, and enhancing customer satisfaction.

FAQs on Process Maps in Six Sigma

1. What are the common challenges encountered while creating process maps?

Creating process maps can be challenging due to factors such as:

- Lack of Process Documentation: Processes may not be adequately documented, requiring extensive interviews and observations.

- Complexity of Processes: Complex processes with multiple steps, dependencies, and decision points can be difficult to map accurately.

- Resistance to Change: Stakeholders may resist change, making it difficult to implement improvements identified through mapping.

2. How can I ensure the accuracy and completeness of a process map?

To ensure accuracy and completeness, involve stakeholders in the process mapping process, conduct thorough reviews, and use data to validate the map.

3. How can I use process maps to improve customer satisfaction?

Process maps can identify bottlenecks and inefficiencies that impact customer experience. By addressing these issues, organizations can improve response times, reduce errors, and enhance customer satisfaction.

4. What are some common mistakes to avoid when creating process maps?

Common mistakes include:

- Oversimplification: Failing to capture sufficient detail, leading to an incomplete or inaccurate representation.

- Lack of Clarity: Using unclear symbols, inconsistent notations, or ambiguous language.

- Ignoring Stakeholders: Neglecting to involve stakeholders in the mapping process, leading to resistance and inaccurate information.

5. How can I effectively communicate a process map to stakeholders?

Use clear and concise language, utilize visual aids like flowcharts and diagrams, and present the map in a structured and engaging manner.

Tips for Effective Process Mapping in Six Sigma

- Start Small: Begin with mapping simple processes before tackling complex ones.

- Involve Stakeholders: Engage stakeholders in the process mapping exercise, ensuring their perspectives are considered.

- Use Technology: Leverage process mapping software for efficiency and accuracy.

- Continuously Improve: Regularly review and update process maps as processes evolve and improvements are implemented.

- Focus on Value: Identify and highlight value-adding activities within the process, eliminating non-value-adding steps.

Conclusion

Process mapping in Six Sigma is an indispensable tool for process improvement, providing a clear and comprehensive understanding of how processes function. By identifying bottlenecks, streamlining workflows, and fostering data-driven decision-making, process maps empower organizations to achieve significant improvements in efficiency, quality, and customer satisfaction. As organizations strive for continuous improvement, process mapping remains a vital component of the Six Sigma methodology, enabling organizations to optimize processes and achieve their strategic objectives.

![Process Mapping: A Complete Guide [+ Templates] - Venngage](https://venngage-wordpress.s3.amazonaws.com/uploads/2022/01/48f8d231-6a05-414e-ad40-9dc33a2e653e-1024x791.png)

Closure

Thus, we hope this article has provided valuable insights into Unveiling the Power of Process Maps in Six Sigma. We hope you find this article informative and beneficial. See you in our next article!

You may also like

Recent Posts

- Navigating The Digital Landscape: A Comprehensive Guide To AT&T’s Service Map For Internet

- Navigating The Keystone Resort Ski Map: A Comprehensive Guide To Exploring The Mountain

- Navigating The Waters: Understanding Nautical Mile Maps

- Navigating The Rails: A Comprehensive Guide To The RTD Train Map

- Navigating Baltimore County: A Guide To The Zoning Map

- A Comprehensive Guide To Parris Island, South Carolina: Navigating The Cradle Of Marines

- Navigating The Waters Of Smith Lake, Alabama: A Comprehensive Guide

- Navigating Kingsland, Texas: A Comprehensive Guide To The City’s Map

Leave a Reply